3D printers have recently gained immense popularity worldwide. The production of 3D printers has increased by many folds due to the rise in demand worldwide.

3D printers are an expensive investment, but they pay for themselves due to reduced production costs.

They are expensive machines that require proper maintenance. If you are looking for personal use, it is available as low as $200 on any leading e-commerce websites.

For commercial purposes, the 3D printing machine can range high in cost depending on the needs and the size and shape of the machine.

Factors Determining Cost of 3D Printing

1. The Technology Used For Printing:

One of the vital factors that determine the cost of 3D printing is the technology used.

There are generally three types of 3D printing. They are better known as

• SLS (Selective Laser Sintering)

• SLA (Stereolithography) or Resin 3D printer

• FDM (Fused Deposition Modeling)

Out of the three, FDM 3D printers are the cheapest, whereas the SLS 3D printer is the most expensive.

The FDM 3D printer machine’s cost is low priced, which eventually decreases the overall cost of this device.

Their filaments are affordable compared to the other two printers and have a low maintenance cost.

2. Size of the Object:

The size of the printing also determines the cost to a great extent. If the printing object’s size is large, more filaments will be required which will gradually increase the printing price.

3. Cost of Infill:

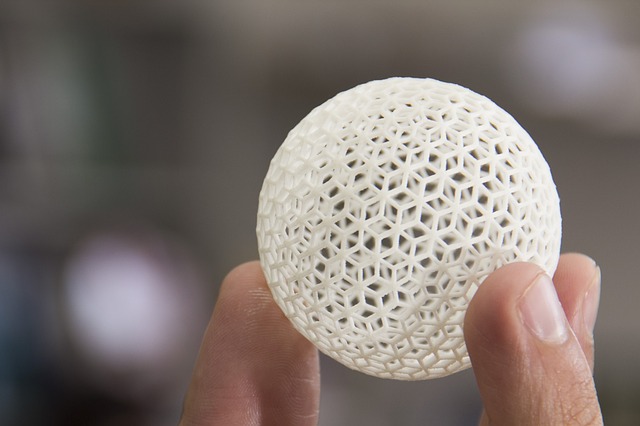

The infill density of any 3D print can affect the cost of printing. The 3D prints do not necessarily have to be 100% plastic so we can adjust the cost of printing by using less infill.

If you want a 3D print that is light and does not have good quality, then the printing price will decrease more as the infill’s low quality costs less.

Similarly, when we use more infill, we get a much more robust and good printing quality, but the price increases significantly.

If you are looking forward to saving money while 3D printing, it is advised to reduce the infill considerably up to the point you think will be viable.

4. Types of Filament:

The types or the brand of filament used to do 3D printing can also influence the overall cost.

There are several types of filaments that come at various prices.

Cheaper filaments can cost approximately $10 TO $15, but if you are looking for an expensive high quality filament, it might cost you anywhere from $40 to $50.

The plastic quality used also influences the cost up to a certain level. There are various kinds of plastics used to get 3D printing done.

ABS is one of the cheapest plastic that costs significantly less. If you are looking for a much more refined, sturdy, and robust print, you have to invest more in the plastic’s quality.

5. Time Required For Printing:

The time taken to print a particular object also determines the overall cost of 3D printing.

If you are printing a big object, the printer is bound to take several days, increasing the cost of electricity by many folds.

It is hard to track the time for printing big objects, resulting in the machine being in use even when the printing is done, increasing electricity costs.

Technological developments in 3D printers now come with an auto shut feature that enables the machine to shut down once the work is done.

6. Layer Thickness:

The thickness of the layer used for printing can influence the price.

This is because if the thickness is more, the time consumption for printing is much more which in turn can increase the price of electricity.

Price of 3D Printers:

3D printers are of several types depending on the cost.

If you are looking for a 3D printer for personal use, you can go for cheaper ones made from cheap quality materials.

Still, the problems here are that these printers have less longevity when compared to their expensive counterpart.

If you are using 3D printers for commercial purposes, it is advised to purchase a printer of good quality.

The time spent on printing in good 3D printing machines is far lesser. Also, the quality of print is better.

According to ekocycle, the types of filament used can additionally enhance the quality of printing. Also, expensive 3D machines have lower maintenance costs and have good longevity.

Specific factors that are mentioned above have an enormous impact on the price of 3D printing.

The price of the 3D printer depends on the technology used. If the 3D printer is of the latest technology, then it is undeniable the cost of printing and other materials will rise.

It is also to ensure that when buying 3D printers, always look for the materials you can invest in.

Try to choose a 3D printer that you can supply with materials as per your budget.

There are many instances where 3D printers become hard to manage as the supplying materials are not possible to buy because of budget crunches. Metals such as aluminum and stainless steel can cost a fortune.

Conclusion

The cost of 3D printing can vary depending on the 3D printer, materials, filament quality, and a lot more factors. All the factors mentioned above play a vital role in determining the cost per print.

If you use lower-quality materials, then the finished product is not that accurate, but the prices decrease considerably.

3D prints’ quality improves when using the best materials, offering a more sturdy and robust output, but the price tends to skyrocket.

Keeping the points mentioned above in your mind, you can easily estimate the cost of 3D printing.