Regardless of the industry, safety continues to be a major focus. Gas monitors safe workers and the environment: Hence, there is a need for gas monitors. Such devices are critical to detecting critical gases and preventing gas hazards. Choosing the most suitable gas monitor includes realizing different characteristics that contribute to its reliability. In this post, we will look at nine key features to look for when selecting a reliable gas monitor.

Sensor Accuracy

Sensors are the driving force behind any gas monitor. This also means that they need to accurately detect the gases to inform the user of the potential hazards quickly. High-quality sensors enable timely detection and help avoid coming into contact with these harmful substances. A dependable monitor should respond with meaningful increases to keep a safe environment.

Durability

The work environment can be a tough place. Gas monitors have to be able to withstand extreme conditions (temperature and physical blows). A device that you can use for a longer time will guarantee durability as well as optimal functioning. Seek out frames wrapped in heavy-duty enclosures and circuitry protected for difficult environments.

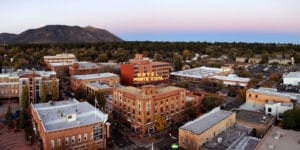

MORE NEWS: How the West Valley technology sector is booming

INDUSTRY INSIGHTS: Want more news like this? Get our free newsletter here

Battery Life

Continuous monitoring demands a long-lasting battery to ensure uninterrupted safety. Frequent battery changes can disrupt safety protocols and increase maintenance costs. Selecting monitors with extended battery life supports continuous operation and reduces downtime. Rechargeable batteries are also more cost-effective, lowering expenses over time. Investing in durable power solutions helps maintain consistent monitoring, enhances workplace safety and reduces overall maintenance burdens. Find high-tech solutions at Ausoptic.

Ease of Use

Gas monitors are made easier to work with via user-friendly interfaces. The device should be easy to use so workers can operate it with minimal or no training. Well-laid-out screens, intuitive controls, and clear directions improve usability. Keeping it simple means that the workforce can do their job without distractions from iffy equipment.

Alarm Systems

Alarms are essential for warning employees about hazards. They use audible, visual, and vibratory signals to ensure alerts are noticed in any environment. Customising alarm thresholds for specific gases enhances safety by enabling immediate responses to dangerous conditions, protecting workers effectively.

Calibration Requirements

Regular calibration is essential for accurate readings. Automated calibration simplifies this process, ensuring each batch of monitors remains reliable without extensive manual effort. Understanding which parts of a device need calibration helps maintain its effectiveness over time, ensuring consistent performance and accuracy throughout the years.

Data Logging

Data logging features monitor employee gas exposure over time, revealing trends and aiding regulatory compliance. Devices that save and export historical data support safety audits and help refine safety plans. This capability offers crucial insights to protect workers, enhancing overall workplace safety. By tracking exposure consistently, businesses can respond proactively to hazards and maintain a secure environment for everyone.

Portability

Portability is essential in many industries. Gas monitors need to be lightweight and compact so workers can carry them easily throughout their shifts. Portable devices offer flexibility, allowing monitoring wherever they are placed. This mobility ensures better safety coverage and helps protect workers in various environments.

Connectivity Options

Most of the gas monitors you find nowadays come with connectivity. Information can be communicated with centric systems through the use of wireless communication technology in real time. Combined, this integration can result in faster decision-making and enhanced safety responses. Opting for monitors with connectivity options will simplify protocols and establish a better flow of communication.

Conclusion

Choosing a reliable gas monitor is crucial for maintaining safety across various work environments. Prioritizing features such as sensor accuracy, durability, and long battery life enhances protection for workers. User-friendly interfaces and clear alarm systems ensure hazards are detected promptly. Additionally, considering calibration requirements, data logging capabilities, portability, and connectivity strengthens overall safety management. A dependable gas monitor safeguards employees and fosters a safer workplace. Investing in high-quality equipment demonstrates a proactive commitment to safety, helping prevent accidents and providing peace of mind for both workers and employers.