The transition to renewable energy is no longer optional — it’s an urgent necessity. As solar farms, wind turbines, and hydropower stations become more critical to global infrastructure, maintaining their uptime and performance has never been more important. One of the most transformative innovations in this space is AI-powered predictive maintenance, which uses advanced deep learning algorithms to detect and prevent equipment failures before they happen.

The Maintenance Challenge in Renewable Energy

Each type of renewable energy asset presents its own set of operational and maintenance challenges:

- Wind turbines are subject to high mechanical stress, gear wear, and unpredictable weather patterns.

- Solar panels degrade over time due to UV exposure, dust accumulation, and temperature cycles.

- Hydropower systems deal with corrosion, sediment buildup, and fluctuating water flows.

Traditional maintenance methods — reactive (fix it when it breaks) or scheduled preventive maintenance — often result in unnecessary downtime or missed failures. To improve performance, energy companies are now adopting smarter strategies, such as renewable energy software development that integrates AI-based diagnostics and automation into asset management systems.

LOCAL NEWS: 100 best places to work and live in Arizona for 2025

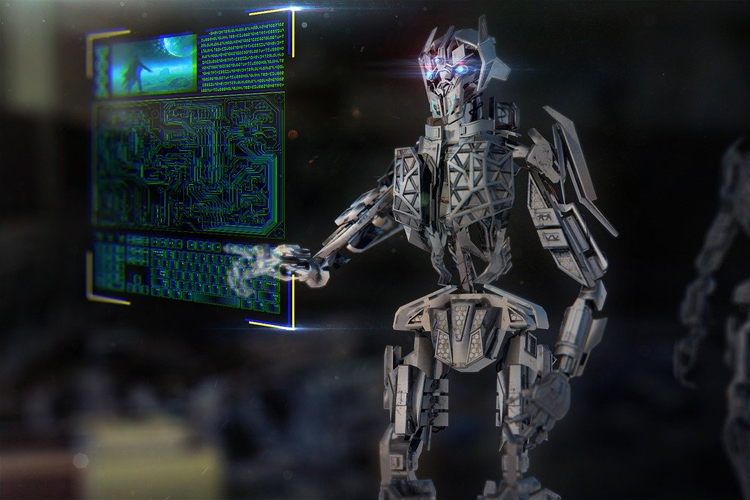

How AI Transforms Predictive Maintenance

Predictive maintenance leverages artificial intelligence to shift from guesswork to precision. Instead of responding to equipment failures, deep learning algorithms proactively identify degradation patterns in real time. This data-driven approach helps maintenance teams intervene before a problem escalates.

Deep learning models excel at detecting complex, non-linear relationships in time-series data from sensors mounted on turbines, panels, and generators. These models evolve with new data, becoming more accurate and effective at predicting failures, reducing manual inspections, and maximizing uptime.

Key AI Capabilities in Renewable Asset Maintenance

AI-driven predictive maintenance platforms for renewable energy typically include several core functions:

Anomaly Detection

Machine learning models identify abnormal patterns that deviate from the system’s usual behaviour. For example, if a turbine’s vibration suddenly increases beyond its historical average, the system flags it for inspection. Algorithms such as LSTM networks and autoencoders are commonly used.

Fault Classification

Once anomalies are detected, classification models categorize the fault — such as overheating, mechanical misalignment, or electrical imbalance — enabling technicians to prepare the appropriate fix quickly and accurately.

Maintenance Scheduling Optimization

AI helps determine when to perform maintenance by analysing component wear, environmental conditions, and historical failures. This leads to smarter scheduling and fewer unnecessary service calls.

To explore how these solutions are developed and deployed, visit https://tech-stack.com/services/deep-learning-development — a resource that supports the design of deep learning systems tailored for industrial and renewable energy applications.

System Architecture Overview

A modern AI-powered maintenance solution typically includes:

- IoT Sensor Layer: Captures data from components, including temperature, pressure, current, and vibration sensors.

- Data Ingestion Pipeline: Cleanses, aggregates, and stores time-series data on the edge or in the cloud.

- AI Modelling Engine: Trains deep learning models on historical and live data to detect early signs of failure.

- User Dashboard: Provides real-time insights, alerts, and predictive analytics to maintenance teams.

When deployed correctly, this architecture allows for scalable, efficient monitoring of energy infrastructure across multiple sites and geographies.

Benefits of AI-Based Predictive Maintenance

The impact of predictive maintenance in renewable energy operations is significant:

- Reduced Downtime: Early fault detection prevents critical failures and unplanned outages.

- Lower Maintenance Costs: Optimized scheduling cuts down on unnecessary inspections and emergency repairs.

- Extended Asset Life: Timely interventions protect equipment from long-term damage.

- Higher Energy Output: Assets run more reliably and efficiently, leading to better power generation.

These advantages directly contribute to improved profitability and help renewable providers deliver consistent, clean energy to the grid.

Challenges and Considerations

Despite its promise, implementing AI in maintenance strategies comes with challenges:

- Data Gaps: Incomplete or low-quality sensor data can compromise prediction accuracy.

- Labelling Limitations: Supervised learning models require failure event labels, which may be rare or incomplete.

- System Integration: Aligning AI solutions with SCADA, CMMS, and ERP systems requires planning and customization.

- Trust and Explainability: Maintenance teams need interpretable AI insights, not just black-box alerts.

To overcome these, companies must prioritize robust data pipelines, edge analytics for remote assets, and human-centred AI interfaces.

The Road Ahead: AI and the Future of Renewable Maintenance

AI’s role in renewable energy maintenance will only grow. Here’s what’s next:

- Digital Twins: AI-powered virtual replicas will simulate equipment behaviour and help test failure scenarios before they occur in the field.

- Edge AI: Real-time analytics deployed on-site will speed up response times and reduce cloud dependency.

- Autonomous Maintenance: Drones, robots, and intelligent agents could soon carry out inspections and repairs guided by AI insights.

As the industry continues to scale, AI-driven maintenance will become a standard component of smart, sustainable energy systems.

Conclusion

AI-powered predictive maintenance is a game-changer for the renewable energy sector. By enabling smarter insights from real-time data, it allows energy companies to minimize risk, extend equipment life, and deliver more consistent energy output.

Deep learning is revolutionising energy infrastructure, from identifying anomalies to optimising scheduling. Explore how these systems can be built, maintained, and scaled, provided by a service provider focused on advanced AI solutions for the energy and industrial sectors.

As global demand for clean energy rises, those who invest in AI-driven reliability today will lead the energy revolution tomorrow.