The meat products must be safe, fresh, and clean when they are delivered to the consumers. That’s because no customer would like to indulge in products that seem stale or unhygienic. This is why the journey of meat processing comes with a lot of responsibilities. To begin with, the meat has to be kept afar from any contaminations. Next in line, the quality checks have to be top-notch and proactive. Since the meat’s condition cannot be sub-standard at any cost. Moreover, undertaking the task of meat processing can be very tedious. On top of this, various factors have to be considered to ensure hygiene is maintained.

Why are control systems important for poultry manufacturers?

Certain standards lay down by Hazard Analysis and Critical Control Point (HACCP) have to be followed. The guidelines majorly circulate an amplified cleanliness and safety protocol to be subsumed by companies.

These standards are ideal benchmarks that have to be maintained by poultry manufacturers. Failing to do so, will attract hefty penalties or every termination of operations for these manufacturers. HACCP conducts regular inspections to check the condition of these factories. This is where systems join in as a helping hand. They assist factories with quality assurances and fulfilling the meat and other products’ disinfection drive.

Control systems and benefits

Control apparatus emerges to be so beneficial because they have a plethora of advantages to offer. They are seen as the core of any meat processing endeavour. In addition, they act like proficient systems that manage various roles seamlessly. They are an indispensable part of any poultry or meat processing factory because of their capabilities. From optimizing energy efficiency to reducing manpower, they have bountiful uses. Moreover, with these systems, manufacturers are also secured of enhanced product safety as well as quality.

Other offerings

The latest development with these systems is the automated ones in the market. The automated systems smoothly reduce the manual work for workers. The electric installations configured in control systems should be designed like https://www.dgs-ps.com/. They are supremely essential because of the efficiency they provide.

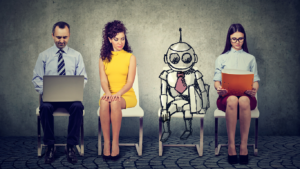

Using this proficient mechanized system will curtail any kind of redundancies that can incur during meat processing. Thus, the use of robust control systems will guarantee a niche quality check of the meat products. Apart from enhancing product quality, meat processing also multiplies productivity levels. The systems are more like robots that can manage multiple functions simultaneously. The deliverables include meat slaughtering, carcass, splitting, trimming of meat, processing of end products. Such robotic systems integrate high-end, sophisticated technology to give optimum results. Apart from reduced time and cost-cutting, magnified precision is an add-on benefit offered by these systems.

Adopting the right strategies is incumbent for poultry manufacturers to ensure their requirements are fulfilled. Hence, a control operator integrated with components that can resist humid environments is a must-use for manufacturers. In the end, safety practices are adapted by any poultry manufacturing unit to increase customer satisfaction.