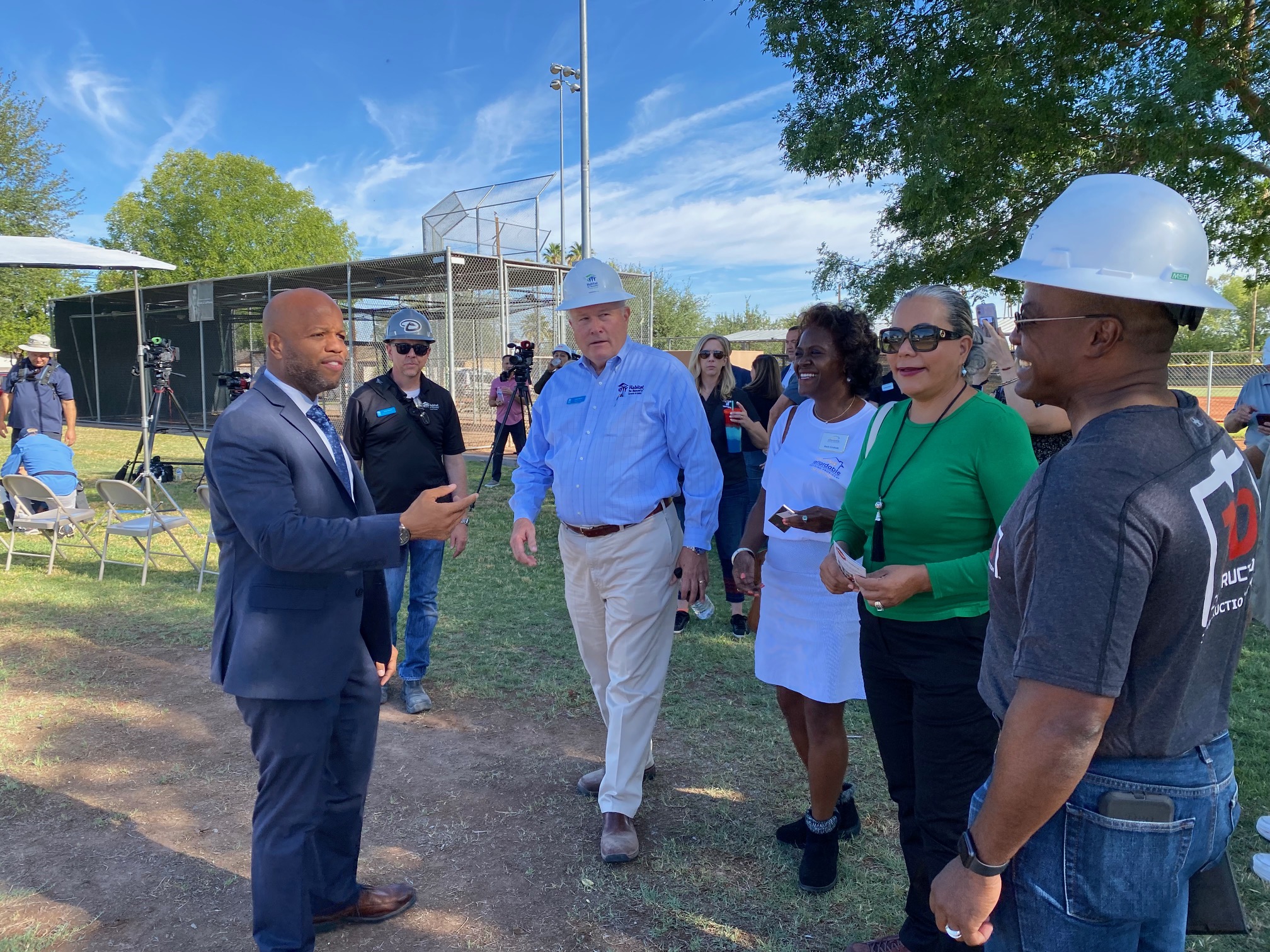

The first 3D-printed home constructed for Habitat for Humanity is underway in Tempe. This morning, Habitat for Humanity President and CEO Jason Barlow, Tempe Mayor Corey Woods, CEO of PERI USA Strydom Groenwald, Principal of 3D Construction Paul McAllister and Team Director and Project Manager for Candelaria Design Damon Wake joined together at the job site for the home for a press conference that also included members of the surrounding community.

ASU graduates and principals for Phoenix-based company 3D Construction, Clarence McAllister and Paul Mooney, Jr. approached Barlow 19 months ago about new and innovative housing solutions. With a lot of planning, support and the inclusion of partnerships, the plan to debut a 3D-printed house through the Habitat for Humanity nonprofit program was set into motion.

READ ALSO: 5 Arizona housing market predictions for 2021

The idea behind a 3D-printed home is to drive down the cost of construction and labor and expedite the time it takes to build the home. A concrete mix that also contains polymers and other materials is put into place by a massive robotic arm structure that extrudes the mix a layer at a time to create the walls with concrete piers. Approximately 70 percent of the home build will be 3D printed and the remaining 30 percent will be built in a traditional manner.

The lack of affordable housing is at an all-time high, especially in Phoenix, currently the hottest housing market in the fastest growing county in the nation. Together, Habitat and the City of Tempe have explored ways to tackle the issues of affordable housing, and 3D printing is an innovative solution that is practical and scalable.

“The City of Tempe and Habitat have been working together for more than 30 years to increase affordable housing for individuals and families in our city,” said Woods. “Right now, the city and Habitat have plans on the drawing board for 16 new homes, including this 3-D printed house. These homes are being built on land purchased by the city to ensure more affordable housing and then donated to Habitat.”

When complete, the custom single-family home will have three bedrooms, two baths and more than 1,600 square-feet of living space. The build for the 3D-printed single-family home has been in the works for 18 months, and it being constructed on a lot that was purchased from the City of Tempe. That lot will also soon include three additional Habitat homes.

“Today is a great day for all the people who made this monumental project a reality,” said Groenwald. “We believe many years from now, people will think back and remember June 9, 2021 as the day that 3D construction printing, a completely new way of building a house, arrived in the U.S.”

“We have a family selection committee and a family service team,” said Dusty Parsons, director of marketing and media for Habitat for Humanity Central Arizona. “Families apply online or by phone, and then they go through an entire process with our family selection committee.” Families have three criteria that must be met to be considered for a home – a need for affordable housing, the ability to pay back a no-interest loan, and the willingness to put in 400 hours of sweat equity into the home build.”

The family that will move into the 3D-printed home in fall 2021 will most likely put in their 400 hours helping to build the three other Habitat homes on their street. For additional information on the home, visit www.habitatcaz.org/3D.