Gears are said to be the most vital parts of any mechanical system, right from a car to industrial machinery, so that torque and motion can be transferred accurately and reliably. The manufacturing process of gears is very cautious as it needs advanced tools and techniques to ensure the complex profiles, exacting tolerances, and smooth finish required for optimum performance. One of the essential tools in achieving efficiency and accuracy in the gear manufacturing process is the High Precision Broaching Machine.

MORE NEWS: 50 commercial real estate projects to know for 2025

This article goes into deeper detail regarding the manufacturing of gears and the way the machines have played a key role in perfecting those gears. By combining and using several machining techniques in conjunction with broaching, gears can be manufactured in strict standards demanded by industries all around the world.

Material Selection: The Foundation of Quality Gears

Starting from selection of appropriate material according to application requirements, material selection for a gear mainly depends on intended applications and is chosen with properties that the gear is likely to achieve. For automobile and industrial applications, strength and resistance to wear can be accomplished with alloy steel, carbon steel, or even ductile iron. Yet in the case of gears made in precision instruments, one can easily find brass, aluminum, or even plastic composites.

High machinability material is considered highly important in the manufacturing process, and it is something High Precision Broaching Machines are really proficient with, and they always seem to produce results, be it of tough material complexity.

Cutting and Shaping: The Core of Gear Manufacturing

The selected material then forms a gear blank using any of the following manufacturing techniques: forging, casting, and extrusion. The base used in the machining processes to come up with the gear teeth profile.

Gear Cutting Techniques

- Hobbing: The most common method of cutting gear teeth is hobbing. A hob is a kind of cutter that rotates with the blank and slowly cuts the tooth form. While effective, however, it is often followed by additional operations to finalize the gear profile.

- Broaching: The process of broaching is very important in the forming of internal gear profiles, splines, or keyways. A High Precision Broaching Machine is well-manufactured for the creation of elaborate shapes in close tolerances, so it is invaluable to the world of gear-making. This process involves pressing or pulling a broach tool fitted with progressively larger cutting teeth through the gear blank, assuring a flawless and accurate finish.

- Shaping and Grinding: Gear shaping employs a reciprocating cutter to generate external teeth, while grinding is used for finishing and getting closer to the specified tolerances. These operations often accompany broaching to make the gear even more precise and accurate in surface quality.

The Role of High Precision Broaching Machines

Broaching is the most significant process in the manufacturing of gears, more so when gears are internal. Precise is very critical. High Precision Broaching Machines are designed for :

- Unmatched Accuracy: This means that the gear teeth and profiles meet precise specifications for peak performance. Tight tolerances are very important for the proper working of gears within mechanical systems.

- Efficient Material Removal: This is remarkably efficient because it involves cutting the material in a measured manner that produces minimal waste.

- Smooth Surface Finishes: High Precision broaching machines leave a very fine, finished finish that usually requires very little additional finishing.

Advancements in Broaching Technology

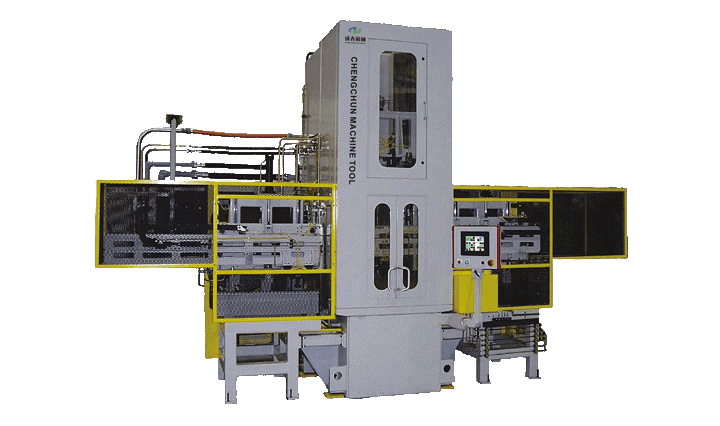

Modern broaching machines, like those on broaching-machine.net, have automation and CNC systems to increase speed and precision. These advancements produce parts more quickly, with increased consistency, and require fewer interventions by the operator.

More so, these machines can easily join other machining processes such that manufacturers can optimally have production lines. For example, gear blank can be hobbed and therefore, broached and lastly ground automatically. Handling will in this case, turn out to be error-free, thus ensuring uniformity of quality throughout the batch.

Heat Treatment and Finishing: Strengthening the Gear

Once the cutting and shaping of the teeth are done, gears undergo heat treatments like carburizing, nitriding, or induction hardening. These processes strengthen the material and make it hard, as well as resistant to wear and allow the gear to withstand operational stresses.

After heat treatment, gears often undergo finishing operations to produce a better surface quality. Most common methods applied to develop perfect gear surfaces for proper mating with other parts are lapping, honing, and grinding. In finishing stages of the process, accurate geometry necessary for final assembly is met by broaching machines.

Quality Control: Ensuring Flawless Gears

In this final stage of gear production, it is ensured that all the gears produced fulfill the requirements of the design as well as the performance needs. Advanced inspection techniques used are coordinate measuring machines and gear measuring tools to ensure the size, surface finish, and the profile of the gear teeth.

High Precision Broaching machines meet these requirements, bringing precision and accuracy to ensure gears that remain unfailing. This further limits defective possibility and promises excellent application performance.

The Future of Gear Manufacturing

Continues to rise the demand on high-performance gears in any line of business, such as automotive, aerospace, renewable, energy industry. In response to increased requirements manufacturers are increasingly embracing advanced technology machines: advanced High Precision Broaching machines. These are the technologies that are at the most innovative front and enable an increase in complexity, reduce tolerances, and consequently improve efficiency in gears made.

This will usher in the age of smart manufacturing through automation and data-driven monitoring in broaching machines. Real-time data can then be tapped to help manufacturers optimize their production processes, reduce downtime, and increase overall productivity.

Conclusion

Geard makes can be multi-dimensional, thus highly precise, and call for the most advanced tools as well as techniques to be used as these can offer quality and performance. This is where unmatched accuracy, efficiency, along with exceptional surface finishes, enable them to play a significant part in modern gear manufacturing-High Precision Broaching Machines-that might be used for cutting delicate profiles of gears or working integratively or in complete harmony with machining and other processes.

Manufacturers who are interested in reliable solutions for gear machining will be interested in High Precision Broaching Machines. The machines presented on broaching-machine.net are the best innovations in the field of redefining possibilities in gear manufacturing, so industries all over the world can rely on the best gears for their mechanical systems.