Precision engineering plays a vital role in many industries where accuracy and reliability are paramount. In demanding work environments, the complexity and variety of operations require innovative solutions that can withstand the test of time and meet specific operational needs. From aerospace to automotive manufacturing, each sector presents unique challenges that precision engineering seeks to address.

This discipline is about precision, and it encompasses quality control, durability, and the ability to operate under varying conditions. As we delve deeper into the aspects of precision engineering, we will explore elements that are important in enhancing productivity and safety, particularly in tough work environments.

The Importance of Quality Materials

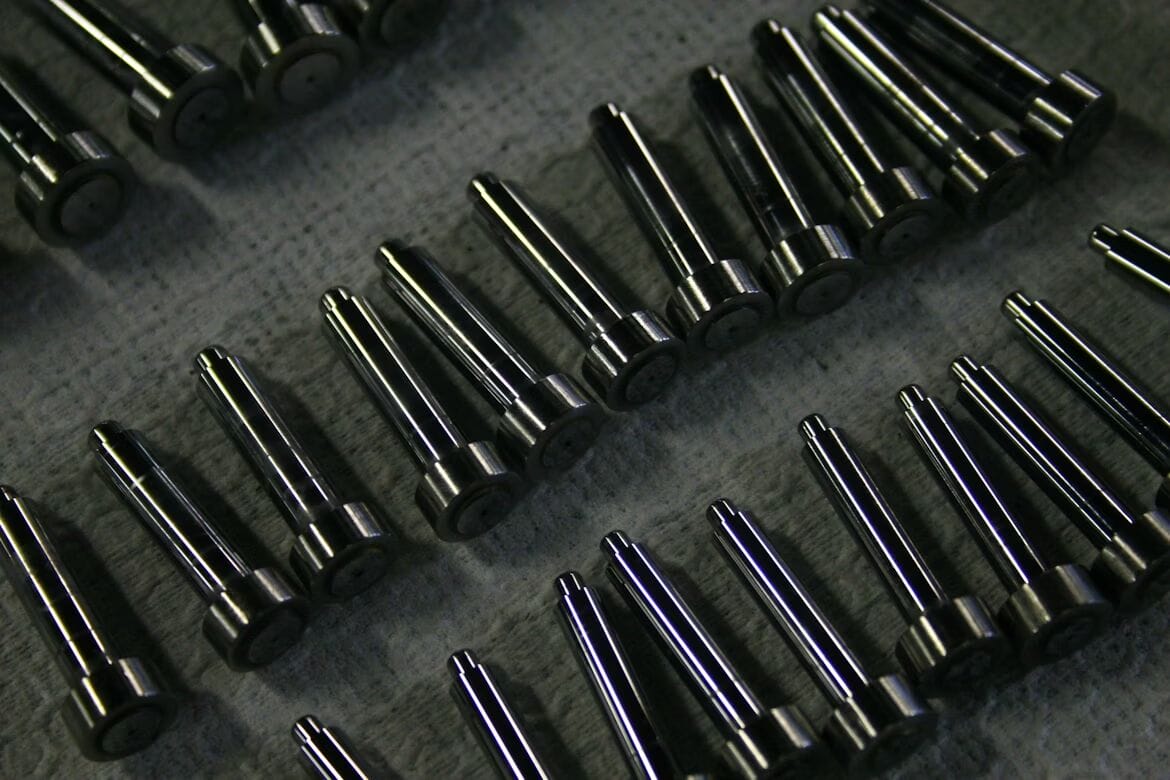

Utilizing high-quality materials lies at the core of precision engineering. Every component crafted needs to withstand operational stresses without deteriorating in performance. Materials like stainless steel, aluminum, and composite alloys are often employed due to their favorable properties, corrosion resistance, lightweight, and strength. These materials ensure that engineered products perform well in extreme conditions, whether exposed to high temperatures, chemical agents, or physical stress. In automotive applications, components are subjected to continuous vibrations and heavy loads. They must endure wear and tear while ensuring a high level of safety.

Opting for subpar materials can lead to failures that compromise the integrity of the machine and pose safety hazards to the operators. Careful selection of materials enhances the reliability and longevity of precision-engineered products, ensuring they meet or exceed industry standards. The manufacturing process itself plays a key role in maintaining quality. Advanced techniques such as CNC machining and additive manufacturing allow engineers to create components with enhanced dimensional accuracy and reproducibility. Such precision caters to performance and minimizes waste and production costs, a critical consideration in demanding work environments where efficiency is key.

LOCAL NEWS: 10 things you may not know are manufactured in Arizona

INDUSTRY INSIGHTS: Want more news like this? Get our free newsletter here

Advanced Manufacturing Technologies

The landscape of precision engineering continuously evolves with technological advancements. Additive manufacturing, commonly known as 3D printing, has reshaped traditional fabrication methods. This innovation allows for the creation of complex geometries that were previously impossible to manufacture using conventional techniques. For industries requiring unique shapes or tailored solutions, additive manufacturing provides the required sophistication without significant material waste. The integration of automation in precision engineering leads to enhanced efficiency. Robotics now plays a vital role in assembly lines, where repetitive tasks are performed with unwavering precision and speed.

This shifts the focus toward more intricate problem-solving tasks and design optimizations that require human ingenuity. The team behind rwmcasters.com says that casters and wheels created with precision engineering are highly effective for heavy machinery, enabling seamless mobility and stability. Without these critical components, operations in manufacturing plants and warehouses can come to a halt, emphasizing their significance. The implementation of Internet of Things (IoT) technology fosters connectivity between machines and systems. Real-time monitoring allows for predictive maintenance, which is invaluable in preventing costly downtime. Engineers can collect data to analyze performance and address issues proactively, thus optimizing operational workflows.

Robust Safety Standards

In demanding work environments, safety cannot be compromised. Precision engineering must comply with rigorous safety regulations and standards to protect both employees and equipment. Understanding the operational atmosphere is important, engineers must evaluate factors such as load capacities, failure modes, and human interaction to design systems that safeguard against hazards. Adherence to safety standards goes beyond compliance, it fosters a culture of safety within an organization.

Regular inspections and maintenance protocols assure the longevity of equipment, while employee training programs ensure that operators are well-informed about safe practices. Implementing machinery with safety features, like overload protection and emergency shut-off mechanisms, demonstrates an organization’s commitment to maintaining a hazard-free work environment.

Certifications such as ISO 9001 for quality management systems ensure that engineering standards are upheld throughout the production process. Such certifications serve as a testament to an organization’s dedication to quality and build trust with clients who expect conformity to safety and reliability standards.

Continuous improvement initiatives, such as periodic safety audits, further strengthen workplace safety by identifying potential risks before they lead to incidents. Incorporating digital monitoring systems can enhance safety by providing real-time alerts and performance tracking. Organizations that prioritize safety see benefits beyond compliance, improved morale, fewer disruptions, and enhanced operational efficiency.

Customization for Unique Needs

Each industry possesses distinct requirements that necessitate customized engineering solutions. Precision engineering allows for the design of products tailored to specific applications, optimizing performance and functionality. Whether in pharmaceuticals requiring sterile environments or in construction needing robust machinery components, customization is key. Manufacturing sites may require specialized casters that can handle various weight distributions, autonomy, and maneuverability on uneven surfaces.

Through customization of designs to meet specific operational needs, manufacturers may successfully increase productivity and throughput. Customization increases the longevity of a product and enhances user satisfaction, resulting in cost savings and improved outcomes.

Working closely with clients during the design phase ensures that engineers gain a comprehensive understanding of their needs. While standardized products serve general purposes, customized solutions enable organizations to maximize their operational capabilities, thereby creating a competitive advantage.

Future Trends in Precision Engineering

As industries continue to innovate, the future of precision engineering looks promising. Emerging trends highlight sustainability, technological integration, and collaborative approaches. A growing emphasis on environmental responsibility drives manufacturers to adopt sustainable materials and processes, thus contributing to greener operations. Companies that prioritize eco-friendly practices often find that consumers are more inclined to support and partner with them.

Technological integration, particularly with artificial intelligence and machine learning, is another area poised for growth. These technologies are enhancing the design process and improving predictive analytics, enabling more efficient production techniques. Collaborative engineering, where multidisciplinary teams work seamlessly across domains, is vital to driving innovation.

Additive manufacturing, commonly known as 3D printing, continues to revolutionize the way components are designed and produced, offering greater customization and reduced waste. The adoption of smart factories and the Internet of Things (IoT) is creating interconnected systems that enhance precision and performance. As data-driven decision-making becomes the norm, companies that leverage digital tools will gain a competitive edge in both speed and accuracy.

Pioneering adaptations in precision engineering push the boundaries of what’s possible and create sustainable and efficient solutions for demanding environments. The emphasis on quality materials, advanced manufacturing technologies, robust safety standards, customization, and a forward-thinking attitude paves the way for enhanced performance and reliability. Adaptability ensures that industries can meet both present demands and future challenges.