Aluminum and stainless steel are two of the most popular metals in the world today. Your needs will determine whether you should use aluminum or stainless steel. Stainless steel is perfect for heavy-duty applications because it is more robust and long-lasting. Aluminum is ideal for portable equipment and transportation because it is lighter and has a high resistance to corrosion.

Stainless steel is used in industrial machinery, automobile parts, medical equipment, kitchen appliances, and construction. Electronics, bicycles, cars, airplanes, packaging, and outdoor furniture all make extensive use of aluminum. Each metal has special qualities that make it suitable for a variety of uses.

In this comparison guide, we shall discuss the differences between aluminum and stainless steel in layman’s terms so that you can have an informed choice to suit your particular requirements.

The difference between aluminum and stainless steel

Apart from the fact that both of these metals have their own importance, strengths, and usages, there are a lot of aspects that make them unique when we discuss Stainless Steel vs Aluminum. Following are some areas that make them different from each other:

- Strength

- Malleability

- Corrosion Resistant

- Medical use

- Electrical conductivity

- Heat conduction

- Magnetism

- Welding

- Weight

- Cost

Let’s have a detailed overview of these points.

LOCAL NEWS: 100 best places to work and live in Arizona for 2025

INDUSTRY INSIGHTS: Want more news like this? Get our free newsletter here

Stainless Steel vs Aluminum: Which is Stronger?

The stronger is stainless steel. It has greater tensile strength, which means it can bear more external pressure without breaking. Its tensile strength begins at approximately 515 MPa and may rise over 1200- 1300 MPa. Stainless steel can absorb more pressure, force, and impact.

The typical tensile strength of aluminum is 100-400 MPa.

Is Stainless Steel heavier than Aluminum?

Yep. Stainless steel weighs approximately 3 times as much. What you might do is to make the same part with both metals, and in either case, the stainless steel will be heavier. This is why aerospace and automotive engineers are banking on aluminum. It is lightweight and consumes less fuel.

How Malleable Are Stainless Steel and Aluminum?

Aluminum has less tensile strength, which makes it efficient for malleability. Malleability is the ability of a metal to be molded into different shapes. The simplest to bend, cut, or press into shape is aluminum. This is why it is employed in the car panels, packaging, and lightweight structures.

Stainless steel is more difficult to work with due to its high tensile strength. To be more flexible, you may choose austenitic stainless steel, such as 304 or 316.

Corrosion Resistance: Which is Better, Aluminum or Stainless Steel

Rust on Aluminium Hull

Both resist rust, but in their own ways. Stainless steel forms a sheath of chromium oxide that is its shield against corrosion. Aluminum also produces an oxide layer of its own (Aluminium oxide), which keeps it non-corroded.

However, stainless steels tend to behave better in severe conditions, particularly where acid, base, or salty water is present. In those areas, aluminum can corrode quickly, especially when exposed to saltwater, unless it is a marine-grade alloy or anodized.

Pro tip: Do not keep stainless steel and aluminum together. It takes a short period of time to kill the aluminum through galvanic corrosion.

Electrical Conductivity of Stainless Steel vs Aluminium:

Aluminum is an excellent conductor of electricity. It is used as an alternative to copper in power lines and electric components.

Stainless steel is a poor conductor; therefore, it is rarely chosen to be used in electric equipment.

Heat Conduction and Temperature Tolerance

Aluminum is a good conductor of heat; hence, it is used in car radiators, cookware, and heat sinks. Stainless steel melts at higher temperatures, and could survive temperatures below 1300°C, whereas aluminum melts at ~660 °C

Aluminum is preferred in case the heat transfer is of concern. Provided that the application needs high-temperature resistance, stainless steel is preferred.

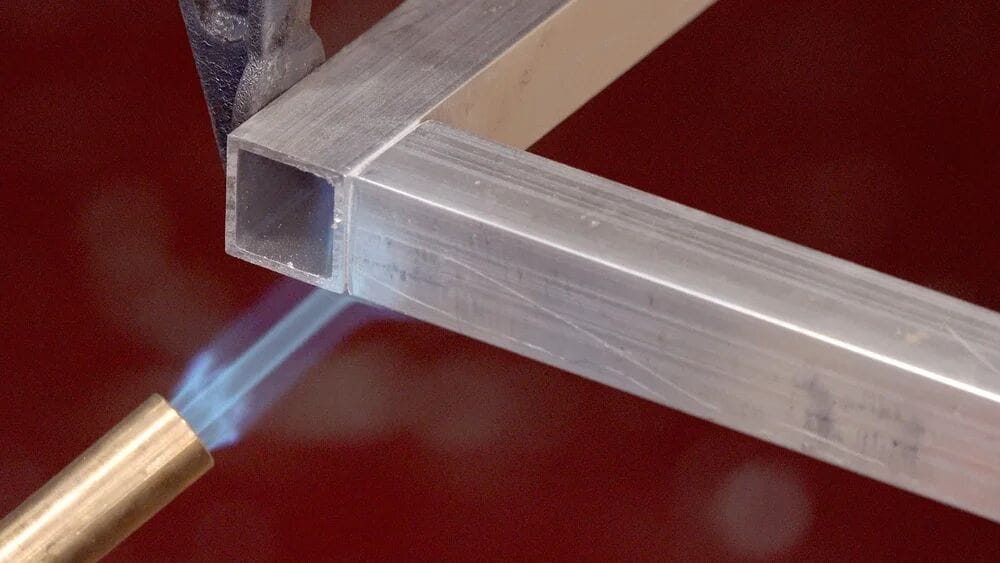

Welding Stainless Steel vs Quick-fix Aluminum.

Welding of Aluminium

The two are both weldable, though aluminum is a harder nut to crack. Its oxide coating is easily melted, and thin sheets can be burned through with ease. Dexterous hands to weld aluminum will be required.

Stainless steel is simpler to handle and can withstand high temperatures easily

Are Aluminium and Stainless Steel Magnetic?

At normal conditions, aluminum is not magnetic due to its atomic structure. It does not respond at all when subjected to strong magnets, even when in close proximity, as it is free from iron. This characteristic enables aluminum to be applicable in situations where it is necessary to use a non-magnetic material, e.g., electronics, aerospace, and MRI rooms of hospitals.

Stainless steel behaves differently. It is magnetized depending on the grade. Ferritic and martensitic stainless steels are more iron-rich and are magnetic. Non-magnetic grades are austenitic grades such as 304 and 316 that are commonly used in kitchens and healthcare. That is why certain stainless steel items will be attracted to the magnet, and some are not.

Food and Kitchen Use

These two metals are kitchen staples. Aluminum can be a great option in pots and pans since it is a great distributor of heat, while Sinks, appliances, and surfaces are made of stainless steel- tough, easy-cleaning, and compatible with food.

Stainless steel tends to win in the case of cooking utensils and preparation, as it does not react with the food.

Is Stainless Steel Better to Use in Medical Equipment and Tools?

Stainless is a true winner in the medical field. It is applied to surgical equipment, implants, and hospital equipment. It is tough, sterilizable, and long-term.

Aluminum is lightweight but softer and less resistant to repeated sterilization, making it less suitable than stainless steel for most surgical tools.

Which is Cost-Effective: Aluminium vs Stainless Steel

Costs shift with the market. Aluminum is normally cheaper per pound. The stainless steel might appear expensive in the short term, but it lasts longer and requires less maintenance.

When you push the price, consider life and longevity, not only the sticker. For professional machining or fabrication services, ProleanTech provides high-quality solutions for both stainless steel machining and aluminum projects.

Advantages of Aluminum

- Lightweight

- High heat and electrical conductivity

- Easy to shape

- Nails normal rust

- Affordable

- Great for aerospace, cars, and packaging

Advantages of Stainless Steel

- Strong and long‑lasting

- Killer corrosion resistance

- Stays strong under pressure

- Food‑safe and medical‑grade

- hermostatic and pressure-resistant.

- Looks good, and it’s easy to clean

- Simple to weld as opposed to aluminum.

Comparison Table: Stainless Steel vs Aluminium

| Property | Stainless Steel | Aluminum |

| Strength | 515–1500 MPa tensile strength. High load-bearing capacity. | 100–400 MPa tensile strength. Weaker but flexible. |

| Weight | About 3 times heavier than aluminum. | Lightweight. Preferred in aerospace and automotive. |

| Malleability | Harder to bend and shape. Austenitic grades (304, 316) improve flexibility. | Highly malleable. Easy to cut, bend, and press into shapes. |

| Corrosion Resistance | Excellent. Chromium oxide layer protects in harsh conditions. | Good but weaker in salty or acidic environments unless anodized or marine grade. |

| Heat Conduction | Survives temperatures above 1400 °C. Not a strong heat conductor. | Strong heat conductor. Melts at ~400 °C. |

| Electrical Conductivity | Poor conductor. Not used in electrical applications. | Excellent conductor. Used in power lines and electronics. |

| Magnetism | It depends on the grade: Ferritic = magnetic; Austenitic (304, 316) = non-magnetic. | Not magnetic under normal conditions. |

| Welding & Machining | Easier to weld and highly suitable for stainless steel machining. | More difficult to weld due to the oxide layer. Requires skilled handling. |

| Medical Use | Preferred for surgical tools, implants, and hospital equipment. | Too soft and porous. Limited use in medical applications. |

| Food/Kitchen Use | Durable, hygienic, and non-reactive. Common in utensils and surfaces. | Good for cookware due to heat distribution, but reactive with food. |

| Cost | Higher upfront cost but longer life and lower maintenance. | Cheaper per pound. More cost-efficient in short-term projects. |

Which Metal Should You Choose?

There’s no one‑size‑fits‑all. Choose the right metal depending on the job requirement. Use aluminum where you want lightweight, high conductivity, and a smaller bill. Use stainless steel when you require hefty strength, durable toughness, extremely resistant corrosion, or medical compliance.

Both metals? They have massive shares in the global industries. It is good to know what each one does best in order to lock in the right fit.