Direct-to-Film (DTF) printing has revolutionized the custom apparel industry, offering unprecedented versatility and quality that traditional printing methods simply cannot match. As we advance through 2025, understanding DTF printing technology has become crucial for businesses looking to expand their custom printing capabilities and meet growing consumer demands.

DTF printing represents a significant leap forward in textile decoration technology. Unlike traditional heat transfer vinyl or screen printing, DTF allows for full-color, detailed designs to be printed on virtually any fabric type, including cotton, polyester, blends, and even leather. This versatility has made DTF printer systems increasingly popular among small businesses, entrepreneurs, and established printing companies alike.

The DTF printing process involves several critical steps that require specific DTF supplies to achieve optimal results. First, designs are printed onto a special DTF film using water-based pigment inks. The printed film is then coated with hot melt adhesive powder, which is subsequently cured using heat. Finally, the design is transferred to the garment using a heat press, creating a durable, vibrant print that can withstand multiple wash cycles.

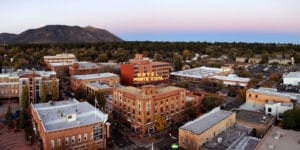

LOCAL NEWS: 100 best places to work and live in Arizona for 2025

INDUSTRY INSIGHTS: Want more news like this? Get our free newsletter here

When selecting a DTF printer for your business, several factors must be considered. Print width determines the maximum size of designs you can produce, with options ranging from desktop units suitable for small-scale operations to wide-format printers capable of handling large production volumes. Print resolution affects the quality and detail of your finished products, with higher DPI settings producing sharper, more professional results.

Essential DTF supplies include specialized films designed for optimal ink absorption and release properties. These films come in various thicknesses and formulations, each suited for different applications and fabric types. Hot melt adhesive powder is another critical component, available in different melting points and formulations to ensure proper adhesion across various materials.

Ink selection plays a vital role in DTF printing success. High-quality pigment inks formulated specifically for DTF applications provide superior color vibrancy, washability, and durability. These inks must maintain proper viscosity and flow characteristics to prevent nozzle clogging and ensure consistent print quality throughout long production runs.

Maintenance of your DTF printer system is crucial for consistent performance and longevity. Regular cleaning schedules, proper storage of DTF supplies, and routine calibration help prevent common issues such as ink settling, nozzle blockages, and color inconsistencies. Implementing proper maintenance protocols can significantly extend equipment life and reduce operational costs.

The business advantages of DTF printing extend beyond technical capabilities. Lower minimum order quantities allow businesses to serve customers seeking small batch or single-item orders, opening new revenue streams previously unavailable with traditional printing methods. The ability to print on demand reduces inventory requirements and eliminates the need for extensive color and size stock.

Quality control measures are essential for maintaining professional standards in DTF printing operations. Regular test prints help identify potential issues before they affect customer orders, while proper environmental controls ensure consistent results regardless of seasonal humidity and temperature variations.

Training and skill development remain critical factors in DTF printing success. Understanding color management, file preparation, and troubleshooting techniques enables operators to maximize equipment potential and deliver consistent, high-quality results that meet customer expectations.

As DTF printing technology continues evolving, staying informed about new developments in DTF printer capabilities and DTF supplies innovations ensures your business remains competitive in an increasingly dynamic marketplace.