There are different varieties of air compressors in the market today. The industrial air compressors vary in terms of power and air pressure they can produce. They also come in various sizes, designs, and motor types. As a result, it is vital to know how to choose the correct air compressor that meets your business needs and gets you results while keeping your costs manageable. For instance, if you buy a system with more power than your business need, you’ll end up spending more than necessary.

Below are some of the essential factors that will help you make the right choice.

Drive System type

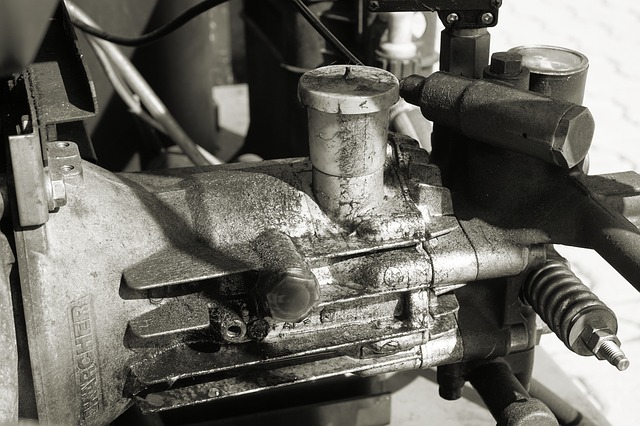

There are two drive system types; you can choose between an electrically powered motor and a diesel-powered motor. Your choice will depend on where you use your industrial air compressor. Electric powered motors are less costly to operate and maintain—however, the electric-powered engines require a constant electricity source. If you are working in job sites where there is no continuous electricity, you need to choose diesel-powered equipment.

Cubic feet per minute (Cfm)

Another crucial factor to consider when choosing a commercial air compressor is determining the amount of power you require. Every manufacture measures the capability of its equipment. Cfm is a unit used to measure the amount of airflow that a compressor can produce. You need to know the different types of cfm measurement, including:

• Standard cfm: This is the measured flow of free air in a standard set of reference conditions. It allows you to compare different units fairly since everything relates to the standard. It is the easiest figure to use when buying a compressor.

• Displaced cfm: this is calculated using the bore, stroke, and revolution per minute. It is usually the highest of the three cfm measurements since it does not consider certain essential variables such as temperature, friction, and heat dissipation.

• Actual cfm: This takes into account the specific environmental conditions when measuring the pump’s output. It is the most important number because it gives a precise measurement. It isn’t easy to calculate.

To determine the amount of airflow you need, you should add up the requirements of all the tools you expect to use at one time with the compressor unit. Then add 30% of that number as a margin of error.

Pounds per square inch (psi)

Psi is the amount of pressure a compressor can produce. The psi of your compressor should be higher than that of your highest rated tool. You don’t need to add the psi of all your tool like you do for cfm. Psi and Cfm are the primary power measurements you need to know when choosing an air compressor.

Electrical requirements

Ensure that the compressor you are buying is compatible with your incoming electrical supply. Most industrial facilities use three-phase power, while residential and commercial buildings utilize a single-phase power. You can hire the services of an electrician to determine the electrical requirements of your facility.

Conclusion

The type of commercial air compressor that is right for your business depends on how you intend to use the equipment and resources available. You need to carefully evaluate your needs and the factors mentioned above to avoid wasting resources on the most potent model in the market.