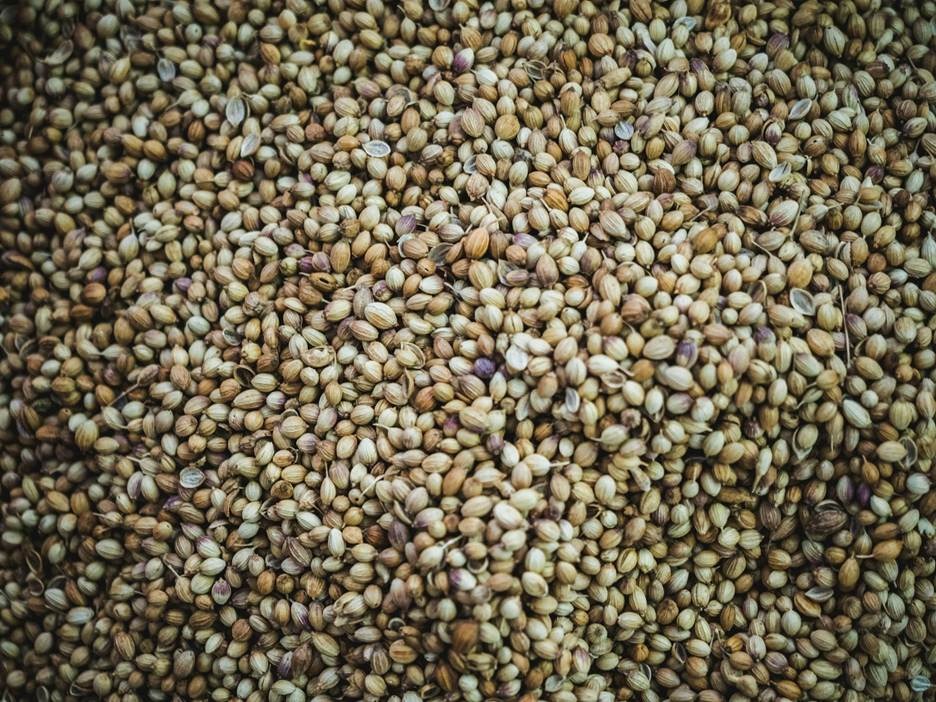

The kit is due on the line in twenty minutes. Trays of micro screws and O rings are ready, sachets of seed varieties are labeled, and a single packet opens short by one. The room goes quiet while someone recounts, someone else checks the scale log, and momentum drains away over a detail that should be simple.

Zero discrepancy is not a slogan. It is a way of building a bench so the promised count is the only possible outcome. When you rely on weight targets and manual top ups, small shifts in unit mass and tiny moments of fatigue creep into your day. The label says pieces, yet the method controls grams. That mismatch invites short packs, silent giveaway, and tense audits.

This article gives you a blueprint for a kitting cell that makes accuracy the default. You will see how to lay out the bench so singulation is calm and predictable, how to design the last ten centimeters before the sensor so pairs cannot slip through, and how to run presets with a two minute acceptance test that any new hire can follow. We will add a clear data flow for audit ready logs, a simple throughput strategy that does not chase the dial, and a seven day pilot that proves the win in your own numbers.

If your goal is to ship exact kits without drama and to defend every count with a clean record, you are in the right place.

LOCAL NEWS: Phoenix housing market outpaces national trends again in 2025

INDUSTRY INSIGHTS: Want more news like this? Get our free newsletter here

What zero discrepancy really means for kitting

The promise on the label is pieces

Kitting lives or dies on a simple truth. Customers and auditors count items, not grams. If a kit says one hundred, anything less is a defect and anything more is a hidden cost. Zero discrepancy means your method controls the count directly, documents it at the moment of pack, and leaves no room for top ups, guesswork, or after the fact reconciliation. It is a workflow choice, not a wish. The counter closes at the preset, the log captures time, lot, operator, and target, and every container that leaves the bench is already proven.

Where weight targets fail in daily work

Weight is attractive because it feels fast. In practice it translates variation in unit mass into variation in count. Moisture in seeds, surface coatings on capsules, supplier mix in micro screws, or slight burrs on stamped parts will nudge unit mass just enough to make a perfect gram value miss the promised quantity. Teams often add a safety margin to avoid shorts, which turns into quiet giveaway across a shift. You then pay the audit tax as staff recount samples to protect quality. The result is slower flow, higher material cost, and a record that argues with itself.

The three control variables that matter

Zero discrepancy kitting comes from three controllable levers.

- Cadence

A steady one by one rhythm is faster than bursts followed by pauses. Aim for a calm stream where the smallest items in the lot travel smoothly. Use a start of block acceptance test that records items per minute so operators know the line is in its sweet spot before real work begins. - Singulation

The last hand width before the sensor decides success. A shaped throat that is one item wide and roughly one item long forces single file travel without stress. A shallow S curve breaks small trains. Track finish does the quiet work. A short polished patch lets stacked pieces slide back into the flow, while a matte patch adds grip where items tend to skate. - Proof

Evidence must be created by the process, not by a second process. Each preset completion writes a line with time, lot, SKU, operator, and target. Add two quick ratios that keep everyone honest. Visible doubles in the final approach divided by items observed, and operator touches per minute. When either rises, clean the window, calm static, and retune one notch before restarting the block. Use an optical seed and parts counter to close at the preset and write a time stamped line that QA can trust.

When cadence is stable, singulation is forgiving, and proof is automatic, the kit that reaches the line matches the label every time and your audit file writes itself.

Bench layout that makes accuracy the default

Station placement, stable table, isolation from vibration

Put the counter where receiving and packing naturally meet so parts do not travel back and forth across the room. Mount it on a heavy, rigid bench that does not flex when someone leans in. Level the surface and check it weekly with a small bubble level. Fit simple isolation pads under the feet so background vibration from printers or conveyors does not ripple through the bowl. Keep the power feed on a clean circuit and park noisy devices like tape dispensers and label applicators on a neighboring table. A quiet bench gives you a quiet lane at the sensor.

Dual container positions to remove idle time

Real throughput rises when the bowl never waits for a human hand. Place two nests for containers at the end of the chute, left and right of center, so one fills while the other is swapped. Set the nests at the same height as the chute outlet so the drop is short and predictable. Add a shallow lip or magnet to hold bags, vials, or jars steady without squeezing. Keep label stock and caps within a single arm reach of each nest. This layout removes the tiny pauses that add up to minutes per hour and it does so without touching feed settings. If you plan alternating fills, review the dual outlet and carousel options before you finalize the nests.

Chute and funnel alignment for clean handoff

Treat the last ten centimeters like a precision tool. The chute should aim straight into the container mouth with no bounce points. If you use a funnel, choose one with a smooth interior and a cone angle that lets items slide without skating. Glass or stainless works best for static control and easy cleaning. Keep the gap from throat exit to container rim short so parts do not fall far enough to tumble. If you must change container sizes, use a quick swap insert that centers the mouth under the stream. Good handoff removes spills, protects coatings, and keeps your count honest at speed.

Light, reach, and small tools where they matter

Even light glare can hide a forming pair near the gate. Place a soft task light that illuminates the final approach without reflections on the window. Mount a small brush, a lint free cloth, and a squeeze bottle of approved cleaner on the bench edge so operators can wipe the window without leaving the station. Add a waste cup for the first seconds of a start so any loose fines or stray pieces do not enter the packet. The fewer steps an operator takes, the more stable your cadence becomes.

A simple layout acceptance drill

Before you run live work, do a five minute check. With the intended container in both nests, run a two minute acceptance test at production settings and record items per minute, visible doubles near the sensor, and any stops. Then perform ten swap cycles left to right without the bowl running and time the sequence. If the average swap is longer than two seconds, adjust nest spacing, lip height, or label placement and repeat. Finish with a paper strip test where a narrow strip rests across the chute exit and the container rim. If the strip flutters during fills, you have bounce to remove with alignment or a shorter drop. You can see a compact reference setup from Elmor for comparison.

Singulation and sensing that prevent pairs and misses

Last ten centimeters design

Think of the final stretch before the sensor as a small machine inside the larger system. Shape a throat that is one item wide and about one item long so parts cannot travel shoulder to shoulder or stack. Keep edges soft so fragile items do not chip and coated parts do not shed. Add a gentle S curve just upstream to break short trains that form in the track. Aim for a straight approach into the sensing zone with no bounce points and a drop into the container that is as short as practical. Film thirty seconds of this zone at production settings and count visible pairs. If you see more than one pair in one hundred passes, narrow the throat a little or polish a short patch where stacks begin.

Track finish strategy

Surface finish is a quiet lever that corrects behavior without more vibration. Where items tend to stack, polish a small section so the upper piece slides back into the stream. Where parts skate and arrive too fast, introduce a matte patch to add grip and slow the cadence by a few items per minute. Make one change at a time and run a two minute acceptance clip so you can see cause and effect. Record items per minute and the visible double rate after each adjustment. When the double rate sits below one percent and cadence is steady, save those settings in the recipe. These small finish adjustments are standard practice on Elmor counting machines and should live in your recipe notes.

Static and dust control

Dry rooms and plastic containers create a cling that looks like counting error. Ground the bench, use glass or metal containers, and keep room humidity in a middle band. If cling persists near the gate, place a small ionizer close to the discharge and retest. Dust blinds sensors and raises false misses. Brush and vacuum dusty lots before they reach the bowl, wipe the window on a schedule rather than only after trouble, and keep a lint free cloth and approved cleaner at the station. Add a short note to the acceptance test log for static and dust conditions so you can read small drifts in context.

The goal of these choices is a calm, single file stream that reaches the optical gate at a predictable speed. When the final approach looks clean to the eye and the acceptance numbers hold, pairs and misses stop stealing minutes from your day.

Conclusion and next steps

Zero discrepancy is a design choice. When you control cadence, shape singulation, and create proof at the moment of pack, the kit that leaves the bench already matches the label. Short packs fade, silent giveaway stops, and audits become a quick review of clean logs rather than a second process.

Make it real with a one week pilot. Pick two kit families, publish a one page recipe for each, and run a two minute acceptance test before every block. Count ten cycle sets with one in ten recounts, record items per minute and visible doubles, and keep exception notes that show the fix and the result in numbers. If the pass criteria hold for five days, you have your new standard.

If you want a proven starting point, evaluate an optical counting machine such as Elmor C1 for tiny and mixed parts, and C1 MAXI for larger shapes. Pair presets with barcode scans so setup lives in a code, not in memory. Store the daily CSV log where support and QA can read what left the bench in seconds. That is how a calm bench turns into calm days.