What does $165 billion look like? It only takes a few minutes of driving west on Loop 303 from I-17 to get a glimpse. Emerging from the desert of North Phoenix, TSMC Arizona is already a colossal sight from the freeway, even at this early stage. The first fab, now producing chips, is a silver-gray monolith that overlooks a vast solar-covered parking lot for employees, vendors and visitors.

As a visitor myself, I parked in the shade before taking the long walk up to a smaller, glass-faced building with a metallic bezel matching the color of the fab next to it. The continuity between the Gown Building and its neighbor goes beyond aesthetics — a skybridge connects the two structures like docked spaceships in a sci-fi movie.

READ MORE: TSMC will invest an additional $100 billion in Arizona, add 3 facilities

GET THE LATEST NEWS: Subscribe for free to get AZ Big Media’s newsletter

Inside, a receptionist standing behind a wide desk exchanged my phone and driver’s license for a security badge. A man sporting a highlighter-yellow safety vest and stickered hardhat introduced himself a few minutes later before unlocking a side door leading to a conference room.

Greg Jackson, director of facilities at TSMC, made easy conversation in a way not all engineers can. In discussing the company’s environmental stewardship, he detailed how strategies around energy efficiency, water conservation and emissions reduction are implemented at the site.

But Jackson’s pride in his work was most apparent once the tour began. With a safety vest and hardhat of my own, our assigned security detail escorted us beyond a gate and onto a golf cart. Passing in front of the completed fab, Jackson explained that the building is about the size of 13 football fields — and it’s just one of six facilities that will eventually populate the site.

The cart turned and parked near another gray structure with 11 cooling towers on the roof. Jackson pointed out that water vapor was only escaping one of the chimney-like features — a testament, he said, to the facility’s ability to reuse the heat it generates.

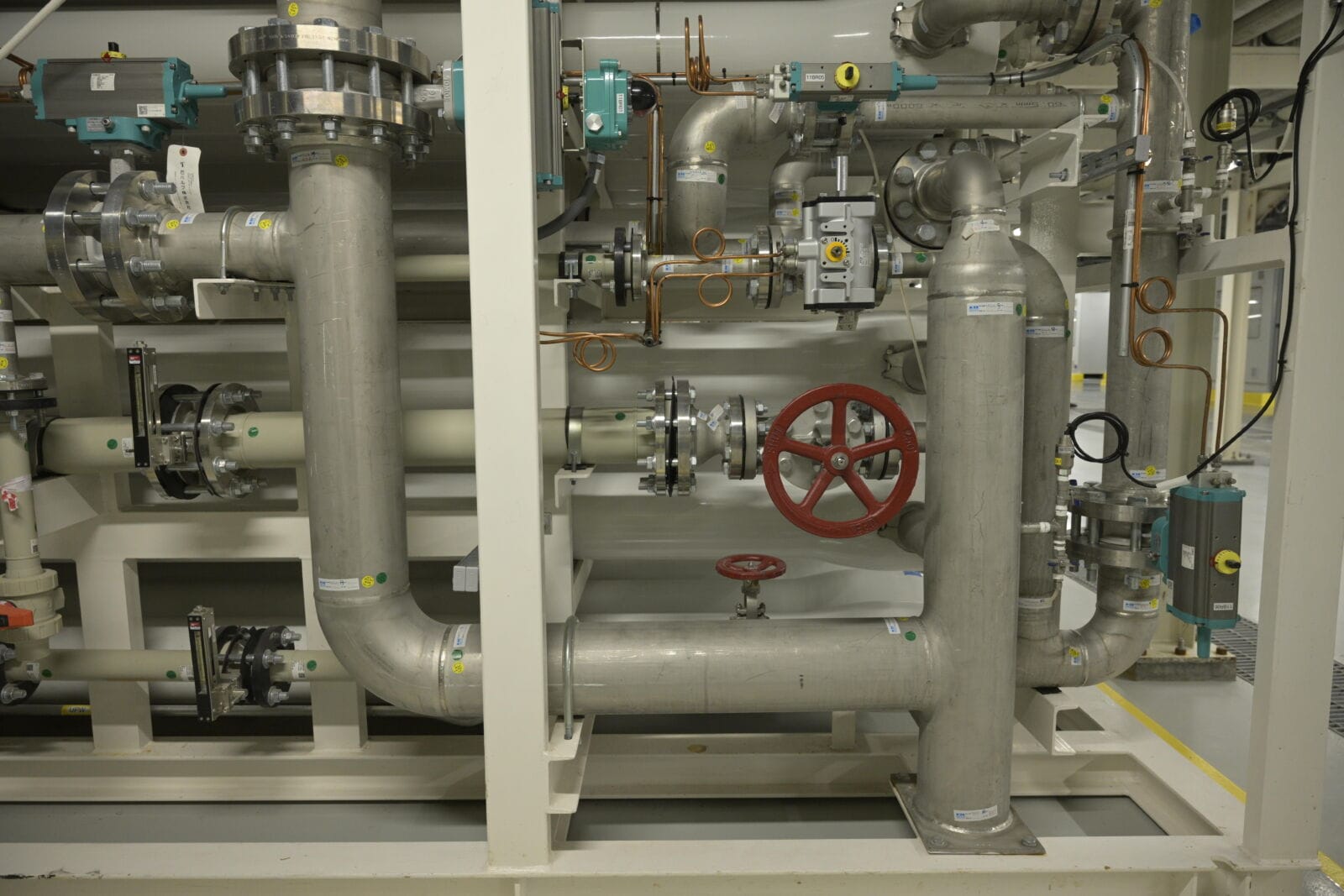

A swipe of a security badge granted us access to the Water Resource Center: a warehouse filled with pumps, angled pipes and massive containers filled with water at different stages in the treatment cycle.

Some of this water, Jackson said, ends up in the cooling towers we saw outside. Once a separate industrial water reclamation plant is finished, he continued, TSMC will recycle water so pure it can be reused in the chip-making process — enabling the site to reach “near-zero liquid discharge.”

Chatting with Jackson as we stood on top of a tank holding 6 million gallons of water — knowing all this was ancillary to the site’s main function — $165 billion remained hard to visualize. But this was a glimpse.

Editor’s note: For details about how TSMC is recycling water, redirecting waste heat back into its processes and ensuring air quality, read the feature in the upcoming May/June issue of AZRE magazine.