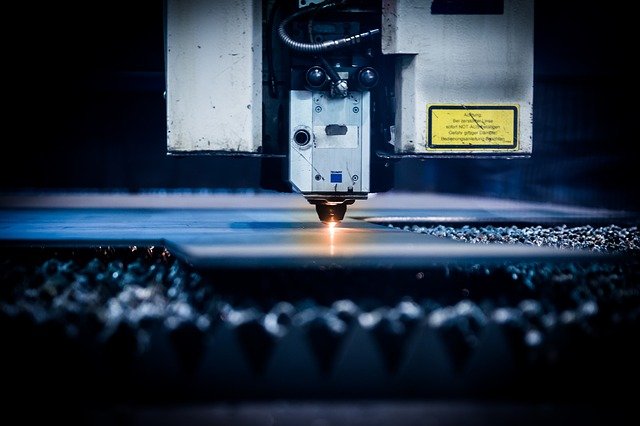

When you step into the laser cutting business, then you need to build up on your skillset with the passage of time. Your team should have the vision and capability to perform the any type of laser cutting including Tube Laser cutting with ease.

However, there is still a margin for errors. We will talk about the mistakes which you must avoid when indulging in laser cutting.

Mistakes to avoid in laser cutting

Not scaling the work piece

It is essential to scale the drawing before setting it up to be cut by a machine. The benefit of the drawing is that you will be able to ensure that the dimensions of your workpiece match. The scaling will depend upon the software which you decide to use.

Making use of inappropriate sources for increasing the cutting speed

There are times when laser cutting businesses make use of the wrong source for improving cutting speed. You need to rely on high wattage for improving the cutting speed. The optimal system of your laser cutting machine also determines the speed.

You also need to improve the way your laser cutter focuses on the beam. The benefit is that you can speed up your work this way.

Making use of less visible lines

Another mistake which most laser cutting businesses do is that they use less visible lines. What is essential is that the metal needs to be marked. Sometimes the machine is unable to detect the light colors.

You need to make use of red lines because you can look forward to improved visibility.

Not making use of margins

Sometimes laser cutting businesses overlook an essential aspect. They do not allow boundaries and margins for cutting the metal piece. What you must keep in mind is that etching needs to be placed in a different layer.

When you follow a standard layout, then laser cutting becomes a more efficient process.

Another serious mistake which most laser cutting businesses do is that they leave the cutter unattended. You should not make this mistake even when you have an automated cutter. Secondly, laser cutter can have serious safety hazards so people should not be loitering around the machine.

Operators should not place any food or drinks near the machine. There needs to be a standard protocol for operating the laser cutting machine. Another mistake workers do is that they move the piece hastily from the machine.

Slight ignorance can cause serious damage to the machine. The laser head alignment can also get disturbed if you move out the piece from the machine in haste. Make sure that you educate all the workers about the standard protocol to operate the laser cutting machine.

The benefit is that the laser cutting process will go smoothly. If you are adopting all the necessary protective measures, then you can monetize on your business. The best approach will be to prepare a checklist of the dos and don’ts when it comes to laser cutting business.