Introduction

Understanding the Function of Peristaltic Hose Pumps

Advantages in Harsh Environments

Applications Across Multiple Industries

The Role of DAE Pumps in Delivering Reliable Solutions

Future Outlook for Peristaltic Hose Pumps

Conclusion

Introducton

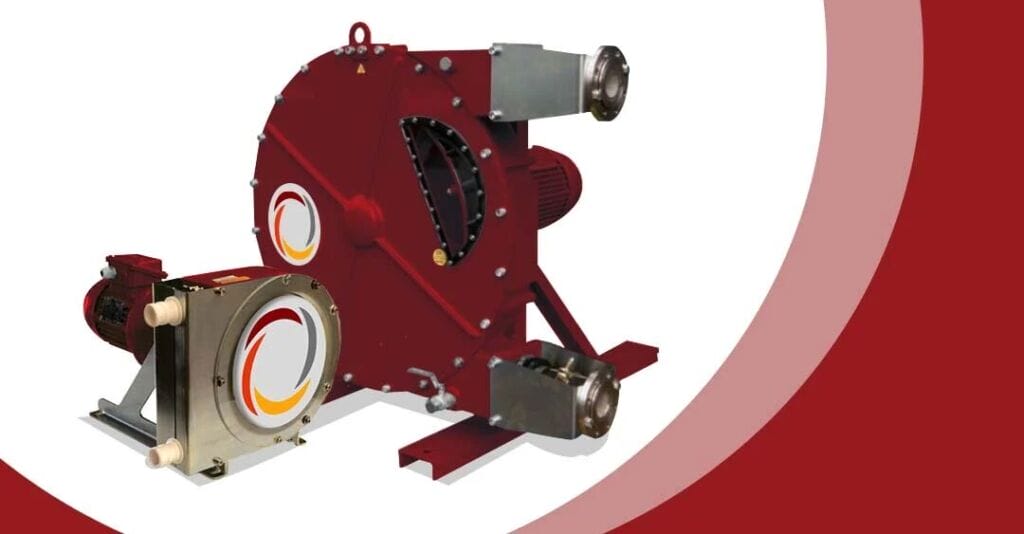

For projects that demand precision, reliability, and durability, the choice of pumping equipment is crucial. Peristaltic hose pumps consistently demonstrate their value across various sectors. These pumps, renowned for their simplicity and efficiency, are essential in applications where traditional pumping systems are insufficient. Their ability to handle challenging materials and require minimal maintenance makes them a trusted solution for professionals globally.

Understanding the Function of Peristaltic Hose Pumps

Peristaltic Hose Pumps function through a simple mechanism: a rotor with rollers or shoes compresses a reinforced hose. This action creates a vacuum, drawing fluid into the pump. The continuous motion of the rotor then propels the liquid forward, maintaining a steady and consistent flow.

With a fully enclosed pumping chamber, these pumps ensure that the fluid never comes into contact with moving parts. This design makes them ideal for handling corrosive, viscous, or abrasive materials that would quickly degrade traditional systems. Their adaptability shines in various applications, from industrial fluid transfer to delicate slurry handling.

Advantages in Harsh Environments

When projects involve abrasive, corrosive, or shear-sensitive fluids, Peristaltic Hose Pumps consistently outperform other pumping technologies. Because the hose is the only component in contact with the pumped material, the risk of contamination or wear on other components is minimized. This ensures longevity even in the most demanding situations.

Peristaltic hose pumps are essential for industries that handle abrasive slurries. Their design facilitates the smooth movement of fluids containing solids, preventing clogging and reducing operational downtime. This inherent reliability is necessary for operations where efficiency and timely execution have a direct impact on profitability.

Additionally, their minimal maintenance needs result in lower overall operational expenses. Replacing hoses is a simple and economical process, unlike the extensive repairs frequently associated with other pump varieties.

Applications Across Multiple Industries

One of the main reasons Peristaltic Hose Pumps are critical is their wide range of applications. They can be found in industries as diverse as construction, mining, chemical processing, food production, and wastewater management.

Peristaltic Hose Pumps are the preferred choice in the chemical sector for precise metering and dosing. Their ability to handle chemical dosing pump technology ensures accuracy when transferring aggressive or hazardous chemicals, preventing leaks or contamination. This not only safeguards the project but also ensures compliance with strict industry regulations.

In the mining and construction sectors, where managing slurries and high-density mixtures is routine, the applications of the Peristaltic Hose Pump play a crucial role. Contractors often depend on abrasive slurry handling equipment for efficient material movement, and peristaltic designs provide unmatched performance. Peristaltic hose pumps offer a reliable and hygienic solution for transferring sludge and other waste materials in municipal wastewater plants.

The Role of DAE Pumps in Delivering Reliable Solutions

Companies like DAE Pumps have embraced the growing demand for durable and versatile pumping solutions. By offering a wide range of Peristaltic Hose Pumps, DAE Pumps supports industries where precision and reliability are paramount. Their models are designed to handle varying flow rates and pressures, allowing them to be customized to meet specific project requirements.

DAE Pumps provides efficient and safe industrial fluid transfer solutions. Their pumps are designed for consistent performance, whether handling abrasive slurries or managing chemical dosing. The brand’s commitment to quality ensures that its equipment can withstand the harshest project environments, benefiting contractors and operators alike.

Future Outlook for Peristaltic Hose Pumps

As industries continue to face evolving challenges, the demand for adaptable pumping solutions will only increase. Future designs of Peristaltic Hose Pumps may incorporate advanced materials for hoses, offering even greater resistance to abrasion and chemicals. Integration with smart monitoring systems could also become standard, enabling operators to track hose life, flow rates, and system pressures in real-time.

With the growing importance of sustainable practices, these pumps are likely to play a larger role in reducing waste and improving energy efficiency. For instance, in applications involving chemical dosing pump technology, improved precision can reduce chemical usage, resulting in both cost savings and environmental benefits.

Conclusion

Peristaltic Hose Pumps have become indispensable across industries due to their unique design, durability, and adaptability. They thrive in environments where conventional pumps fail, particularly in projects involving industrial fluid transfer systems or abrasive slurry handling equipment. Their role in ensuring safe and efficient chemical dosing pump technology also demonstrates their broad utility.

With companies like DAE Pumps leading the way, contractors and engineers can access high-quality pumping solutions tailored to meet the demands of modern projects. As industries continue to evolve, the importance of these pumps will only grow, solidifying their place as a cornerstone in efficient project execution.