Site safety should be the top priority whether working on a small scale paint job or an industrial construction site. Ultimately, site safety is also the duty of the employer no matter the size or type of work site. This means providing employees with a workplace that is both safe and healthy. So how do you make your construction site safer and cut down on risks? In this post, we will introduce you to 5 safety risks and how to prevent them.

Why is construction site safety so important?

Site safety is so important because it helps to prevent accidents and even fatalities. It also helps to ensure employers, employees, and other site users are able to operate in an environment safe from health risks. It includes ensuring there are safety precautions in place, staff are trained appropriately, personal protective equipment (PPE) is available if needed, and making safety central to all site practice.

A safe site is also a more efficient site. Unsafe sites will lead to accidents that force people off work making it harder to complete jobs on schedule. When employees know they are being looked after, and their health and safety is being respected their morale is also likely to be boosted. Boosted morale tends to equate to higher productivity. OSHA 10 online training is another ideal way to set your employees up to succeed and mitigate the risk for workplace injuries before they occur.

5 safety risk common on construction sites (and to how to prevent them)

According to stats from the Occupational Safety and Health Administration, there are 14 deaths every day in the construction industry. That adds up to 1 in every 5 workplace deaths taking place in construction. More than any other industry. Here, we outline 5 of the most common risks and steps you can take to prevent them:

Slips and Falls

Falls made up a third of construction industry deaths in 2018. This makes them the most common type of accident in the construction industry that leads to death. To avoid this, suitable surface protectors should be installed when necessary. Ideally, these should be waterproof and slip-resistant, and appropriate protective footwear should be worn on-site at all times.

In addition, OSHA recommends that:

• Holes in the floor should be covered or guarded;

• Open-sided platforms should have a guard rail;

• Install guard rails around any dangerous equipment;

• Install safety nets/use harnesses when necessary;

• Keep floors clean, dry, and free from clutter;

• Ensure workplaces are free of known dangers;

• Provide PPE, if needed, at no extra cost to workers, and;

• Train workers about potential hazards.

Being struck by an object

The second most common cause of death on construction sites is being struck by a falling object. This is also a common cause of fractures and other serious injuries. An example of how this can occur is when hoisting bricks to the top of a building in a bucket, the bucket twisting, and a brick landing on a worker. However, there are numerous other ways this can occur.

To prevent this type of injury, hard hats should be worn at hall times on construction sites. Guards should be provided anywhere where falling debris could be an issue, including on conveyor belts or anywhere where pinch points may be an issue.

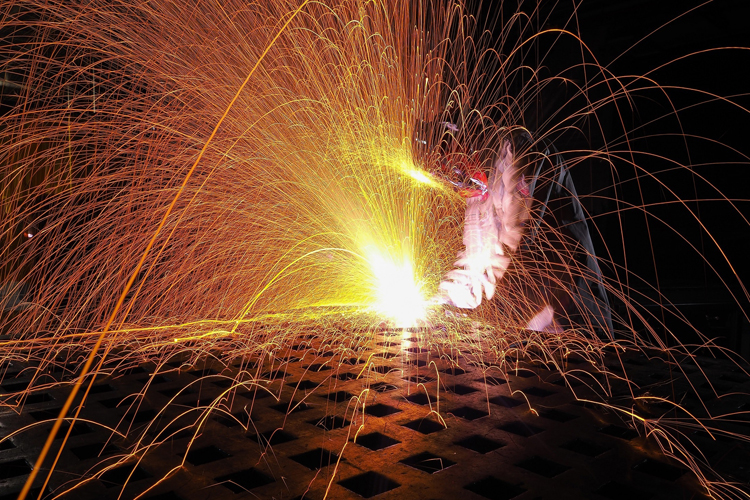

Respiratory risks

From asbestos to dangerous particles from materials like cement, harmful gases, smoke, and dust. Respiratory risks are a major risk area when it comes to protecting employee health. When working in environments where respiratory risks exist, it is important to choose the right protective gear. This includes suitable PPE for the conditions and making sure the risks are minimized.

To minimize asbestos risk it is important to check where it is present on any job. Only people with appropriate PPE and specialist training can do any work on these areas and they must not be disturbed by other work. In terms of reducing the risk from dust particles in the air, face masks can be used. Tools like wet saws and drills can prevent it from spreading in the air also.

Electrocution

Electrocution is also one of the top 4 killers on construction sites. This usually happens as a result of unsafe equipment, an unsafe environment, or due to unsafe work practices. Ensuring employees are given suitable protective gear is vital when it comes to working with electricity. According to OSHA, insulation, guards, grounding, and effective work practice training can help to prevent the risk of electrocution.

Heat exhaustion

When wearing protective gear or working, working hard in enclosed spaces, or laboring in the hot sun all day, the risk of heat exhaustion is also very real in the construction industry. It is important to train staff to be aware of the risks and symptoms (hand cramps, blurred vision, dizziness, headaches, and nausea). Employers should also provide cool water and encourage employees to drink at least a pint an hour.

Workplace safety should be central to all on-site decisions. This means effective training, provision of protective gear, and putting safety at the heart of site practice.